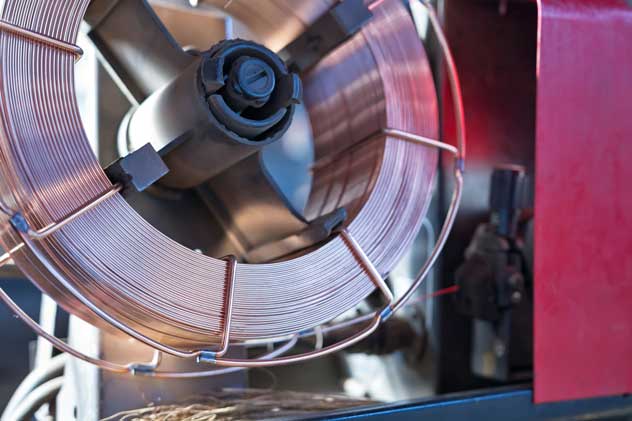

WELDING CABLES

NBR (Nitryl & Butyral Rubber) with single and double insulated along with extra flexible copper conductors. These robust welding cables are designed to carry high currents under rough usage conditions and are capable to withstand high temperature.

Single Core PVC Insulated Copper Conductor (Unsheathed)

Industrial Cables, 1100 Voltage Grade

Conductor

Bright Annealed Electrolytic grade bare copper conformingto IS8130 specifications. 0.50 Sq.mm and 0.75 Sq.mm cables are made of class 5 conductors. 1 Sq.mm, 150 Sq. mm and 2.50 Sq.mm cables are made of class 2 conductorss 4.00 Sq. mm and 6.00 Sq.mm are made of class 5 conductors

Insulation

FR cables will have primary insulation with natural PVC of FR- TYPE A properties and skin coating with coloured PVC with FR- Type A properties as per IS-5831

Standard colours

Red/Yellow/ Blue/Black/Green/Yellow with green tracing. Any other colours can be made on specific order.

Packing

90 metres coils in cartons, 180 metres coilsin poly wrap packing for projects.

The number and diameter of conductor strands are for reference only. The actual sizes may vary. As per IS-8130, if the resistance of a cable is within the specified maximum limit then it is accepted as conforming to the nominal cross-sectional area specified for that size.

Features

Ultra high performance flexible welding lead with double insulation

Better flame retardant properties

Excellent flexibility with minimum 6D bending radius

Outstanding toughness and durability

High resistance to cuts, tears and abrasion

Resistance to oil, solvent and chemicals

Excellent ozone and weather resistance

Application

Designed for the high current connection to automatic or hand metal arc welding electrodes.

Suitable for flexible use under rugged condition on assembly lines and conveyor systems, in machine tools, in automatically operated lines and spot welding machines.